Part IV - Trial Run Dry Assemblies

With over 200 mortice & tenon joints to make throughout this project, I decided to set up the small bench morticer from my former professional workshop. I mainly used this machine as a pillar drill and not a morticer, which meant all the chisels have had little use and are still razor sharp.

Here it is set up in the garden on a small table as a sit down job - perfect.

Before moving on with the joints, I've now glued up all 4 tapered posts which I showed in the previous installation as a dry assembly. I wasn't sure whether to paint the joint dividers black or leave them in the natural oak. I've gone with the black as per drawings and painted them before glue assembly. I'm very pleased with the result.

The pair on the left with the mortices are for the rear frame and the pair on the right with no mortices are for the porch.

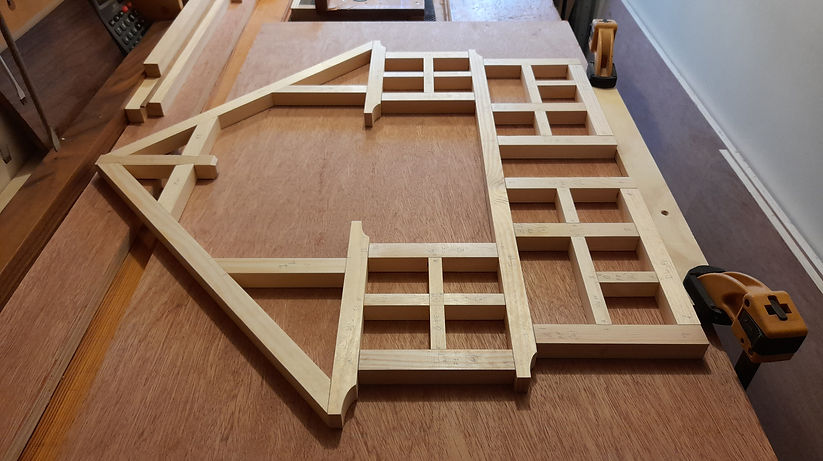

Moving on with the frames, and first up is the front frame with all of the joints made and ready for a dry assembly trial run. Please note; the joints will look much neater when they are glued/cramped and the frames have been cleaned up with a sharp block plane and 400g sand paper.

I am using mortice & tenon joints throughout Project Merlin. On a full size scale, these joints would have one, two or three hardwood pins (predominantly oak) through the complete joint, known as 'draw-bore pins' or pegs. This old traditional method is designed to permanently pull the joint firmly together. I will be drilling 2mm pins through all of the joints at a later stage, which will be more authentic than structural.

Below is showing a 2mm hardwood dowel I shall be using as the pegs throughout the build.

The ground & first floor of the front frame.

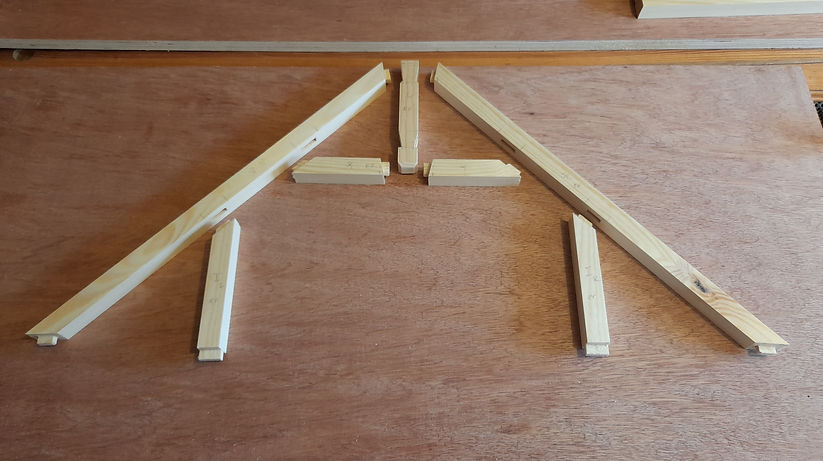

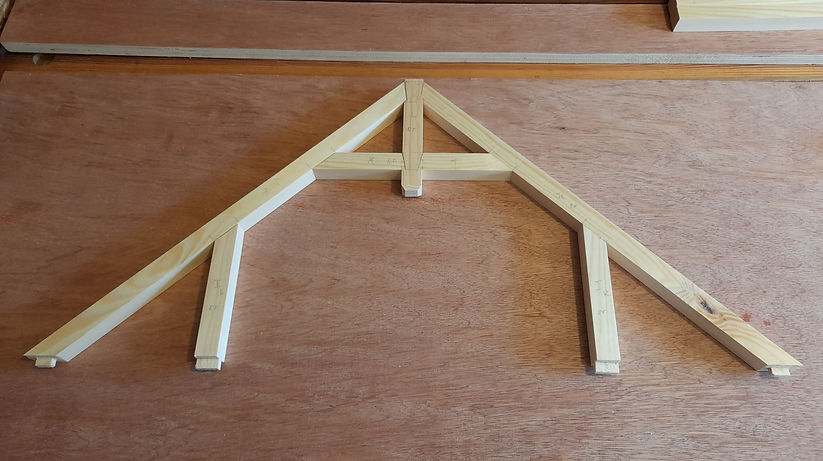

The roof truss.

The complete frame excluding the braces and narrow studs.

Standing in position on its base.

And here is the rear frame - again, the joints will look much neater when they are all glued and the frames are sand paper finished.

The ground floor.

The ground & first floor.

I am using a king post and split collar arrangement. In a full size project, this joint would normally include a loose spline connecting the split collar through the mortice of the king post with a series of pegs, but I am opting for a slightly easier method by using stub tenons on the connection of the king post and split collar.

The complete frame excluding the braces and narrow studs.

Amazingly, the frame stood unaided as a dry assembly.